At Allied Metrics, we offer oil seals made from the highest quality materials to ensure durable, reliable seals for a variety of applications. Our state-of-the-art machining services allow us to deliver custom seals to meet customer requirements for quantity, size, style, profile, and materials.

Oil seals close spaces between moving or stationary mechanical components to prevent lubricants like grease and oil from escaping, while also preventing dust, dirt, moisture, and other contaminants from entering the seal. Also known as shaft seals, dirt seals, lip seals, or grease seals, the primary components of any oil seal include an inner metal ring, which provides structural support, and a spring, which provides interference for effective sealing.

The outer part of an oil seal is made of metal or rubber, depending on the intended application. Metal-cased seals are a cost-effective option used when the housing bore is made of the same material, allowing for equal expansion and contraction of the materials during use. Rubber-cased oil seals provide a tight fit and are commonly used when metal-cased seals have the potential to fail. They are corrosion-resistant and capable of withstanding extreme temperatures and pressures.

How Oil Seals Work

When installed, the oil seal’s flexible lip is placed against the rotating shaft, and the casing is pushed into the housing for support. It is crucial that the sealing lip is lubricated to avoid overheating caused by friction.

When choosing a type of oil seal, it is important to consider factors such as environment, shaft speed and pressure of your machine, temperature, and the type of materials the seal will interact with during use. These considerations will ensure that you choose a compatible oil seal for your particular machinery and help you select the right color, size, and lip material or sealing element.

Which Materials Make up Seals?

Oil seals come in a vast range of materials and compounds. Even older materials, such leather, are still used today. Nitrile is among the most common materials for oil seals but is slowly losing ground to PTFE, which is gaining popularity due to its effectiveness in high-speed applications.

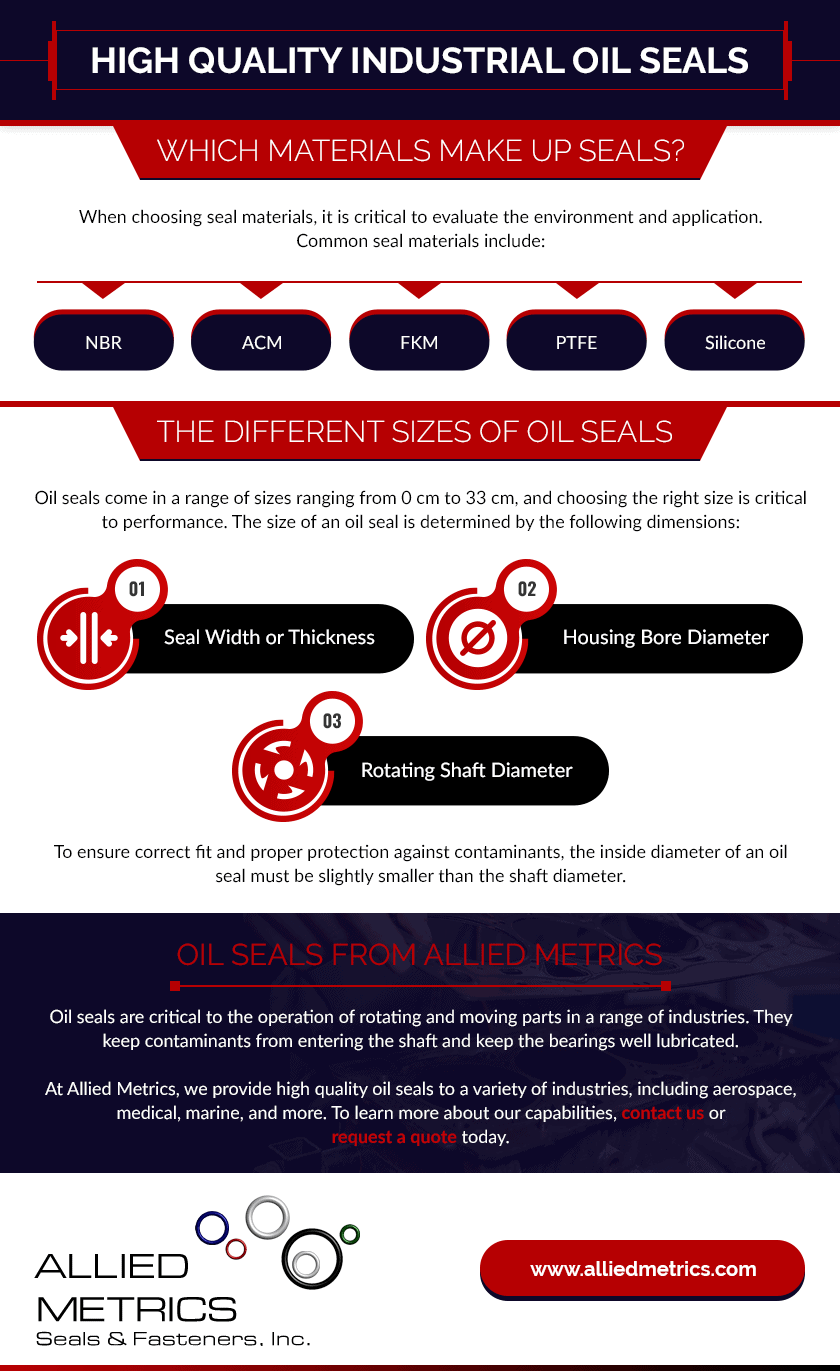

When choosing seal materials, it is critical to evaluate the environment and application. Common seal materials include:

- NBR. NBR has high wear resistance and good oil resistance. It is an ideal choice in moderate-high temperatures and cold temperatures from -40°C to 100 °C.

- ACM. ACM handles high temperatures but is not suited for applications exposed to lower temperatures ranging from -30°C to 150 °C. It has good oil resistance and moderate wear resistance.

- FKM. FKM is ideal for extremely high temperatures and moderate low temperatures ranging from -25°C to 200 °C. It also has very good wear and oil resistance.

- PTFE. PTFE excels at extreme operating temperatures from -80°C to 200 °C. It also boasts extremely good oil resistance and very good wear resistance.

The Different Sizes of Oil Seals

Oil seals come in a range of sizes ranging from 0 cm to 33 cm, and choosing the right size is critical to performance. The size of an oil seal is determined by the following dimensions:

- Seal width or thickness

- Housing bore diameter

- Rotating shaft diameter

To ensure correct fit and proper protection against contaminants, the inside diameter of an oil seal must be slightly smaller than the shaft diameter.

Applications of Oil Seals

A wide range of industries rely on oil seals to ensure optimal operation of mechanical assemblies. Components in the industrial and automotive fields, such as pumps, fans, electric motors, and other rotating or moving parts, use oil seals to maintain lubrication and keep contaminants from entering the shaft. Seals are especially useful in applications exposed to extreme environmental temperatures and pressures.

Oil Seals From Allied Metrics

Oil seals are critical to the operation of rotating and moving parts in a range of industries. They keep contaminants from entering the shaft and keep the bearings well lubricated. At Allied Metrics, we provide high quality oil seals to a variety of industries, including aerospace, medical, marine, and more. To learn more about our capabilities, contact us or request a quote today.