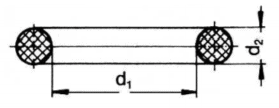

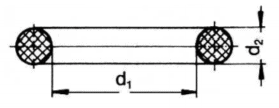

O-Ring Overview

O-rings are an inexpensive and reliable solution with simple mounting requirements for dynamic and static sealing applications. They are mechanical gaskets that are seated into a groove and compressed during assembly, creating a seal between two or more parts to block the passage of liquids or gases.

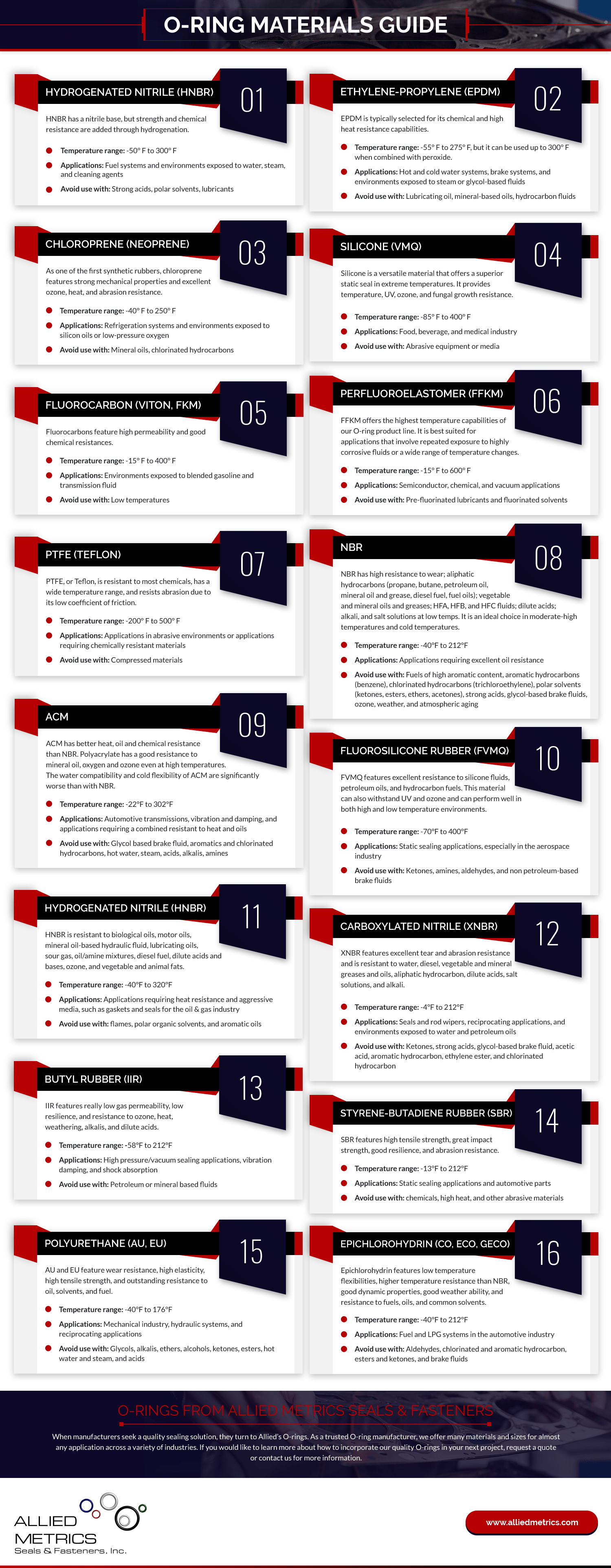

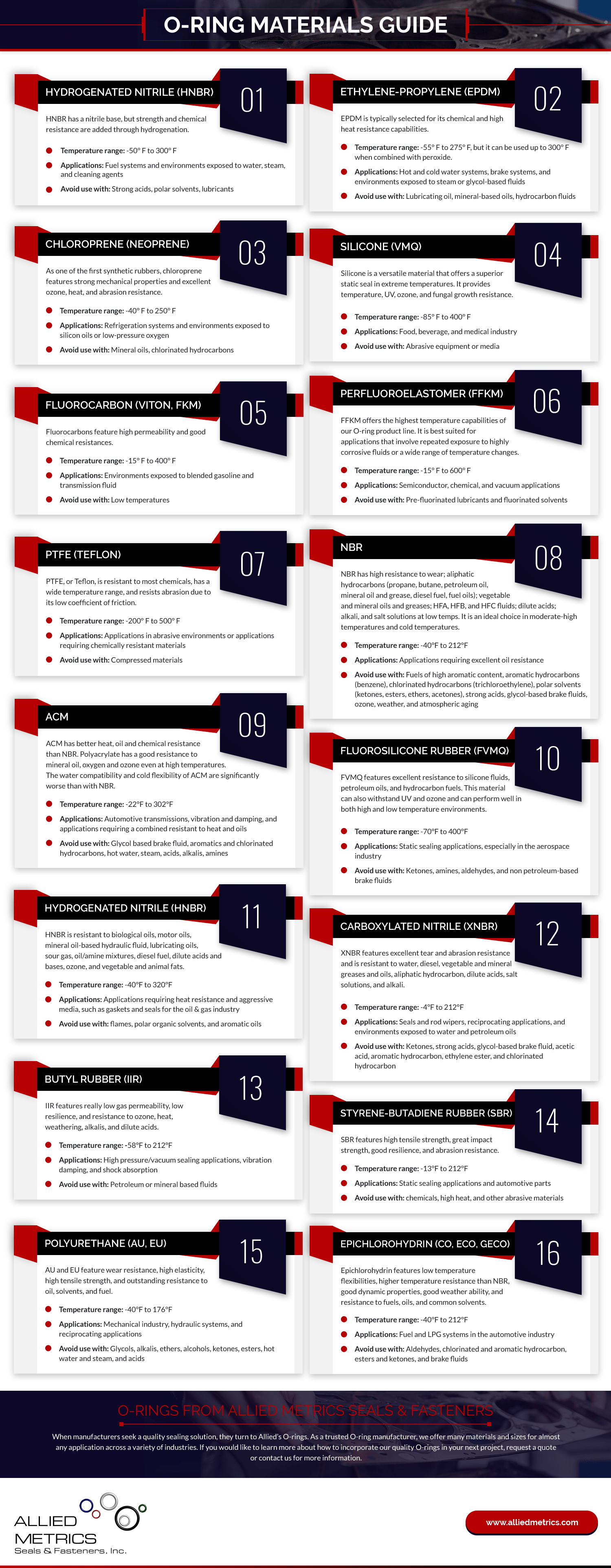

O-Ring Materials Guide

O-rings are manufactured from a variety of pliable materials, and sizes can be customized to fit your application requirements. It is important to understand the different features and benefits of each O-ring material, such as temperature range and chemical compatibility, to ensure choosing the material most suitable for your intended use.

Below is an overview of the materials we work with, their temperature range, their general applications, and when to avoid that particular substance.

Hydrogenated Nitrile (HNBR)

Click to Expand

HNBR has a nitrile base, but strength and chemical resistance are added through hydrogenation.

- Temperature range: -50° F to 300° F

- Applications: Fuel systems and environments exposed to water, steam, and cleaning agents

- Avoid use with: Strong acids, polar solvents, lubricants

Ethylene-Propylene (EPDM)

EPDM is typically selected for its chemical and high heat resistance capabilities.

- Temperature range: -55° F to 275° F, but it can be used up to 300° F when combined with peroxide.

- Applications: Hot and cold water systems, brake systems, and environments exposed to steam or glycol-based fluids

- Avoid use with: Lubricating oil, mineral-based oils, hydrocarbon fluids

Chloroprene (Neoprene)

As one of the first synthetic rubbers, chloroprene features strong mechanical properties and excellent ozone, heat, and abrasion resistance.

- Temperature range: -40° F to 250° F

- Applications: Refrigeration systems and environments exposed to silicon oils or low-pressure oxygen

- Avoid use with: Mineral oils, chlorinated hydrocarbons

Silicone (VMQ)

Silicone is a versatile material that offers a superior static seal in extreme temperatures. It provides temperature, UV, ozone, and fungal growth resistance.

- Temperature range: -85° F to 400° F

- Applications: Food, beverage, and medical industry

- Avoid use with: Abrasive equipment or media

Fluorocarbon (Viton, FKM)

Fluorocarbons feature high permeability and good chemical resistances.

- Temperature range: -15° F to 400° F

- Applications: Environments exposed to blended gasoline and transmission fluid

- Avoid use with: Low temperatures

Perfluoroelastomer (FFKM)

FFKM offers the highest temperature capabilities of our O-ring product line. It is best suited for applications that involve repeated exposure to highly corrosive fluids or a wide range of temperature changes.

- Temperature range: -15° F to 600° F

- Applications: Semiconductor, chemical, and vacuum applications

- Avoid use with: Pre-fluorinated lubricants and fluorinated solvents

PTFE (Teflon)

PTFE, or Teflon, is resistant to most chemicals, has a wide temperature range, and resists abrasion due to its low coefficient of friction.

- Temperature range: -200° F to 500° F

- Applications: Applications in abrasive environments or applications requiring chemically resistant materials

- Avoid use with: Compressed materials

NBR

NBR has high resistance to wear; aliphatic hydrocarbons (propane, butane, petroleum oil, mineral oil and grease, diesel fuel, fuel oils); vegetable and mineral oils and greases; HFA, HFB, and HFC fluids; dilute acids; alkali, and salt solutions at low temps. It is an ideal choice in moderate-high temperatures and cold temperatures.

- Temperature range: -40°F to 212°F

- Applications: Applications requiring excellent oil resistance

- Avoid use with: Fuels of high aromatic content, aromatic hydrocarbons (benzene), chlorinated hydrocarbons (trichloroethylene), polar solvents (ketones, esters, ethers, acetones), strong acids, glycol-based brake fluids, ozone, weather, and atmospheric aging

ACM

ACM has better heat, oil and chemical resistance than NBR. Polyacrylate has a good resistance to mineral oil, oxygen and ozone even at high temperatures. The water compatibility and cold flexibility of ACM are significantly worse than with NBR.

- Temperature range: -22°F to 302°F

- Applications: Automotive transmissions, vibration and damping, and applications requiring a combined resistant to heat and oils

- Avoid use with: Glycol based brake fluid, aromatics and chlorinated hydrocarbons, hot water, steam, acids, alkalis, amines

Fluorosilicone Rubber (FVMQ)

FVMQ features excellent resistance to silicone fluids, petroleum oils, and hydrocarbon fuels. This material can also withstand UV and ozone and can perform well in both high and low temperature environments.

- Temperature range: -70°F to 400°F

- Applications: Static sealing applications, especially in the aerospace industry

- Avoid use with: Ketones, amines, aldehydes, and non petroleum-based brake fluids

Hydrogenated Nitrile (HNBR)

HNBR is resistant to biological oils, motor oils, mineral oil-based hydraulic fluid, lubricating oils, sour gas, oil/amine mixtures, diesel fuel, dilute acids and bases, ozone, and vegetable and animal fats.

- Temperature range: -40°F to 320°F

- Applications: Applications requiring heat resistance and aggressive media, such as gaskets and seals for the oil & gas industry

- Avoid use with: flames, polar organic solvents, and aromatic oils

Carboxylated Nitrile (XNBR)

XNBR features excellent tear and abrasion resistance and is resistant to water, diesel, vegetable and mineral greases and oils, aliphatic hydrocarbon, dilute acids, salt solutions, and alkali.

- Temperature range: -4°F to 212°F

- Applications: Seals and rod wipers, reciprocating applications, and environments exposed to water and petroleum oils

- Avoid use with: Ketones, strong acids, glycol-based brake fluid, acetic acid, aromatic hydrocarbon, ethylene ester, and chlorinated hydrocarbon

Butyl Rubber (IIR)

IIR features really low gas permeability, low resilience, and resistance to ozone, heat, weathering, alkalis, and dilute acids.

- Temperature range: -58°F to 212°F

- Applications: High pressure/vacuum sealing applications, vibration damping, and shock absorption

- Avoid use with: Petroleum or mineral based fluids

Styrene-Butadiene Rubber (SBR)

SBR features high tensile strength, great impact strength, good resilience, and abrasion resistance.

- Temperature range: -13°F to 212°F

- Applications: Static sealing applications and automotive parts

- Avoid use with: chemicals, high heat, and other abrasive materials

Polyurethane (AU, EU)

AU and EU feature wear resistance, high elasticity, high tensile strength, and outstanding resistance to oil, solvents, and fuel.

- Temperature range: -40°F to 176°F

- Applications: Mechanical industry, hydraulic systems, and reciprocating applications

- Avoid use with: Glycols, alkalis, ethers, alcohols, ketones, esters, hot water and steam, and acids

Epichlorohydrin (CO, ECO, GECO)

Epichlorohydrin features low temperature flexibilities, higher temperature resistance than NBR, good dynamic properties, good weather ability, and resistance to fuels, oils, and common solvents.

- Temperature range: -40°F to 212°F

- Applications: Fuel and LPG systems in the automotive industry

- Avoid use with: Aldehydes, chlorinated and aromatic hydrocarbon, esters and ketones, and brake fluids

O-Rings from Allied Metrics O-Rings & Seals

When manufacturers seek a quality sealing solution, they turn to Allied’s O-rings. As a trusted O-ring manufacturer, we offer many materials and sizes for almost any application across a variety of industries. If you would like to learn more about how to incorporate our quality O-rings in your next project, request a quote or contact us for more information.