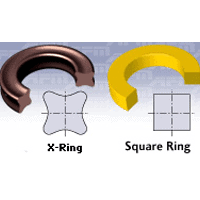

Though O-rings are perhaps the most widely used sealing solution, X-rings offer an excellent alternative for many sealing applications. An X-ring is designed to fit between two parts to fill the gap between them once compressed, whereas an O-ring sits in a groove and compresses when assembled in both dynamic and static applications.

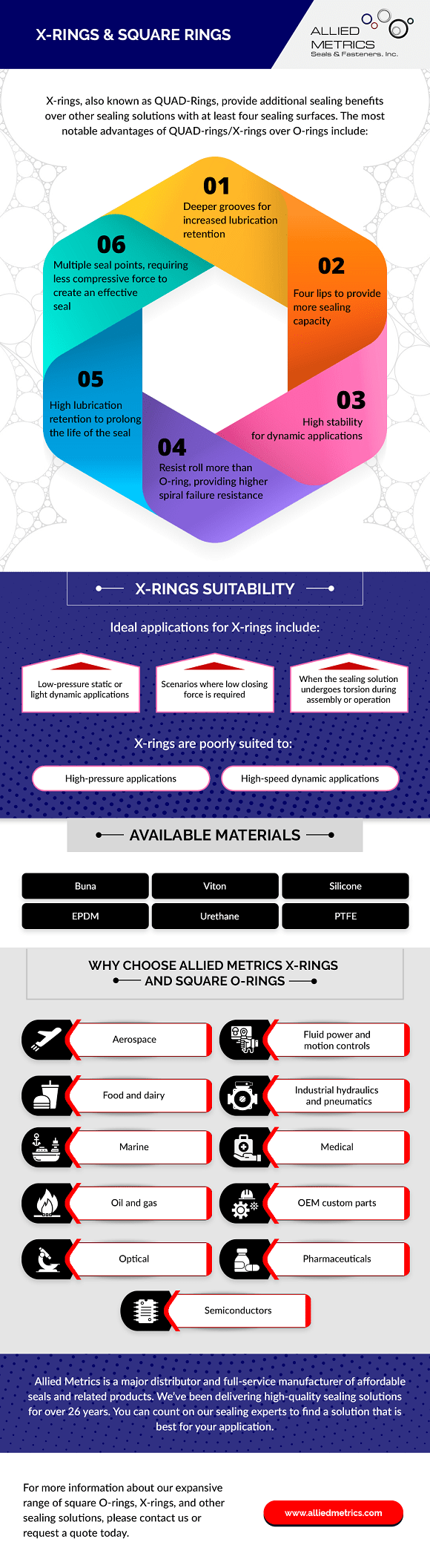

X-rings, also known as QUAD-Rings, provide additional sealing benefits over other sealing solutions with at least four sealing surfaces. The most notable advantages of QUAD-rings/X-rings over O-rings include:

- Deeper grooves for increased lubrication retention

- Four lips to provide more sealing capacity

- High stability for dynamic applications

- Resist roll more than O-ring, providing higher spiral failure resistance

- High lubrication retention to prolong the life of the seal

- Multiple seal points, requiring less compressive force to create an effective seal

X-Rings Suitability

While X-rings provide an efficient seal across a wide range of industries, they aren’t always appropriate as an alternative for O-rings. When considering an X-ring for your application, first determine the environmental conditions that will be present to ensure it will perform optimally.

There are certain applications for which QUAD-rings are not suitable and others where they will excel. Generally, X-rings are well-suited for static and non-rotary dynamic applications and they offer high sealing efficiency in even lower pressure scenarios.

At low pressures, an X-ring will slightly compress to establish a seal. When pressurized, it fits into the groove towards the clearance gap, allowing a small area that can be filled with lubricant for noise reduction and extended seal life.

Ideal applications for X-rings include:

- Low-pressure static or light dynamic applications

- Scenarios where low closing force is required

- When the sealing solution undergoes torsion during assembly or operation

X-rings are poorly suited to:

- High-pressure applications

- High-speed dynamic applications

Advantages of Square O-Rings and Square Rings

Square rings have a round top view and square-shaped side view. They provide a superior sealing solution at a lower cost than comparable seals. Available in a variety of sizes, square rings can typically be used interchangeably with O-rings by fitting into the same grooves on existing applications. A square ring may directly replace an O-ring in most situations.

In many cases, a square ring will outperform the original O-ring. As such, there is no need to redesign a product or procedure when making the switch to square rings. Square rings are manufactured in a variety of material options, including Buna, EPDM, Teflon, and Viton.

Why Choose Allied Metrics X-Rings and Square O-Rings

Allied Metrics provides X-rings and square O-rings for companies across multiple industries and a wide variety of applications. Our company is proud to serve the following industries:

- Aerospace

- Fluid power and motion controls

- Food and dairy

- Industrial hydraulics and pneumatics

- Marine

- Medical

- Oil and gas

- OEM custom parts

- Optical

- Pharmaceuticals

- Semiconductors

Allied Metrics is a major distributor and full-service manufacturer of affordable seals and related products. We’ve been delivering high-quality sealing solutions for over 26 years. You can count on our sealing experts to find a solution that is best for your application.

For more information about our expansive range of square O-rings, X-rings, and other sealing solutions, please contact us or request a quote today.