When it comes to food-grade applications, it is vital to choose a suitable material for your gasket or seal. High temperatures and harsh chemicals can degrade some materials, making them unsuitable for contact with food.

You can count on Allied Metrics O-Rings & Seals, Inc. to help you choose the right food grade gasket for your needs. Our guide will help you select suitable materials for your application.

Why are Food Grade O-Rings and Seals important?

O-rings and seals are used to seal structures such as pipes, tubes, pistons, and cylinders. Placing them between two surfaces prevents liquids and gases from leaking.

For the food industry, such components are crucial as they transform raw food materials into shelf-ready foods through bottling, canning, fermentation, freezing, pasteurization, and steaming.

Food grade gaskets are necessary forvarious reasons:

-

When the seal material matches the cleaning chemicals, the interval between planned maintenance and production yield can be maximized.

-

With coating technology, friction characteristics of elastomer seals are improved, wear resistance is enhanced, and insertion forces are reduced.

-

These are critical to processing equipment’s performance and can significantly impact the commercial success of food and beverage products.

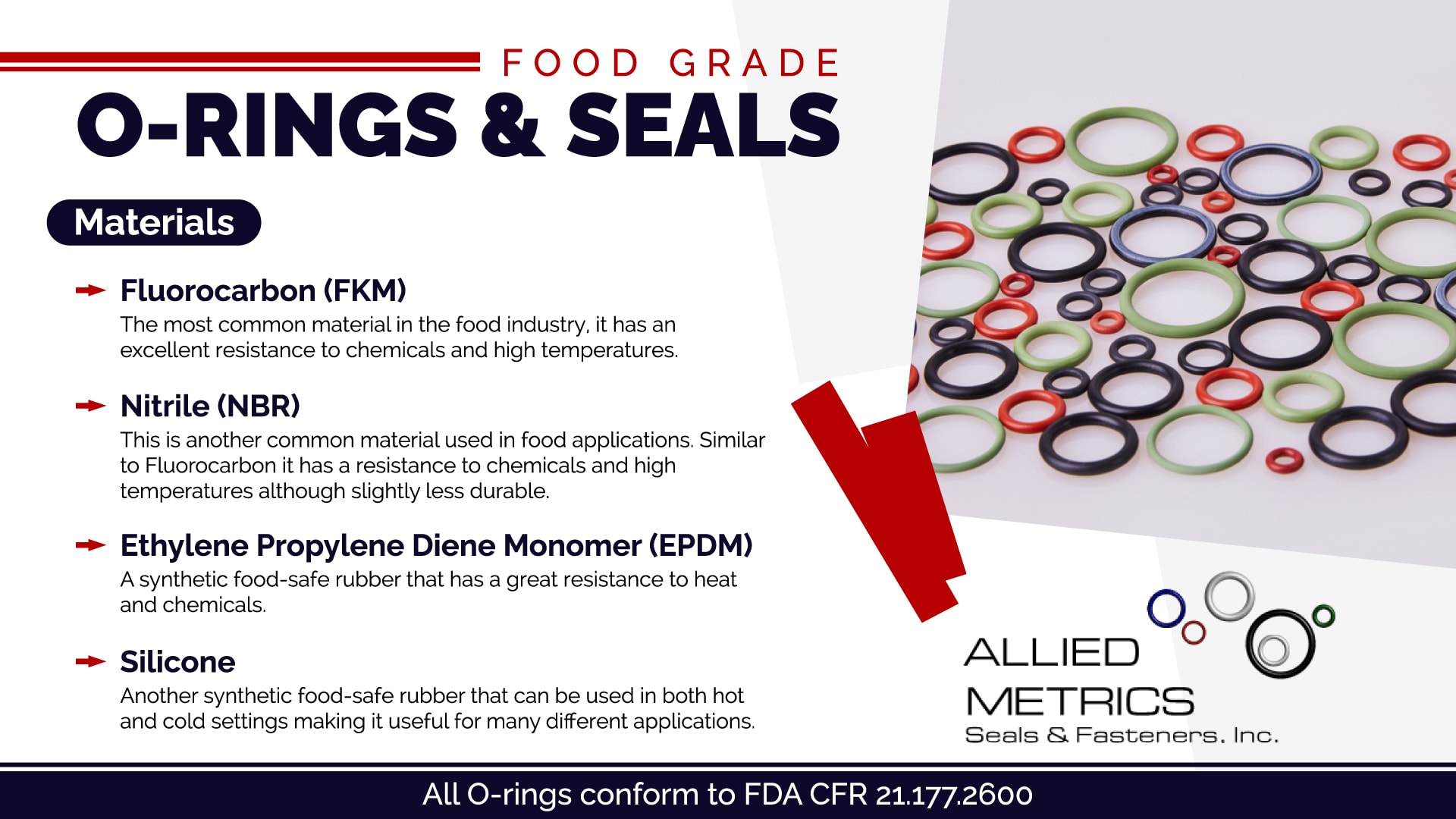

Materials Used For Food Grade O-Rings and Seals

There is a variety of food grade gasket materials for o-rings and seals. These materials are all well-suited for food processing due to their different properties. The following are the materials used in our Food Grade O-Rings and Seals:

-

Silicone O-Rings: The dielectric properties of silicon are excellent, and it offers resistance to heat, ozone, and corona. The material is also highly flexible at low temperatures and resistant to many oils, chemicals, and solvents.

-

PTFE O-Rings: Polytetrafluoroethylene, or PTFE, is an electrical and thermal insulator that can withstand various temperatures. It has a high level of temperature resistance, similar to silicone. Furthermore, it is excellently resistant to abrasion and stickiness and is commonly used due to its extreme malleability.

-

Viton O-Rings: A high-performance rubber, Viton is resistant to ozone, oxygen, mineral oil, fuels, hydraulic fluids, aromatics, and many organic solvents and chemicals.

-

Buna O-Rings: Buna (also known as NBR) is rubber with high wear resistance, excellent mechanical properties, and oil and fuel resistance.

-

EPDM O-Rings: As a weather-resistant and UV-resistant material, ethylene propylene diene monomer, or EPDM, is ideal for situations that require exposure to the elements. In addition to being flexible at low temperatures, it is chemically resistant and electrically insulating.

What To Look For in Food Grade O-Rings and Seals

Food grade o-rings and seals are safe for direct food contact. An o-ring must be from synthetic or natural materials that can withstand the conditions where it will be applicable. It is also considered safe in food applications, processing, or manufacturing.

There are a few things to consider when choosing the suitable material for your food grade gasket:

-

Find out the intended use of the gasket. If you need a gasket in direct contact with food, you’ll want to ensure what food-grade material is made from.

-

Take into consideration the environment for the gasket. You’ll want to ensure the material can tolerate high temperatures. If your application exposes the gasket or seal to high temperatures, you will need high-temperature food grade material that can withstand the heat. Some materials, like fluorocarbon and silicone, can handle up to 400 degrees Fahrenheit.

-

Consider whether the material will be chemically compatible with the food or beverage. The quality of food grade seals varies. Select a seal specifically designed for food processing. FDA-approved materials are used in these seals to ensure food safety from processing until it reaches the market.

The Right Material Makes A Difference

Whether you’re looking for an o-ring or seal for your next food processing project, Allied Metrics O-Rings & Seals is here to help. With over 26 years of experience in the industry, we have the knowledge and expertise to recommend and supply the best possible product for your needs. Contact us today to discuss your requirements – our team will be happy to assist you!