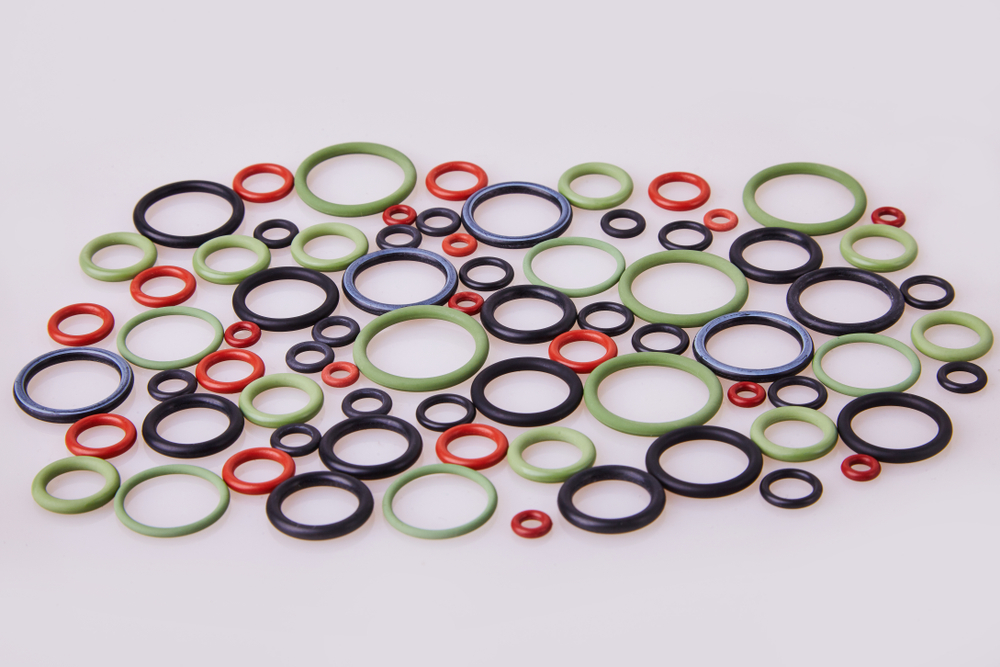

Allied Metrics Seals & Fasteners, Inc. is a reliable and reputable manufacturer of high-quality metric o rings for various industries. These industries typically operate hydraulic systems where o-rings are required to prevent leaks. However, it’s also ideal for different applications, so we offer them in different sizes and materials for various applications.

Our o-rings are highly durable and offer superior sealing performance to protect your equipment from any damage. Our quality assurance process guarantees that each of our o-rings meets industry standards for quality and safety.

We provide superior customer service, so you can be sure your needs will always be addressed. In addition, we can work with you to ensure your project’s success.